Ever since Percy Spencer first melted a chocolate bar in his shirt pocket in 1945, industrial microwave power’s primary source has not changed (until now). Our familiar tube-based friend, Magnetron, has been the sound power source for our industry for over half a century. It has served us well, figuratively and literally (think of all the late-night microwavable mac and cheese). But as technology advances, the stealthy Magnetron can no longer meet the demands required by this industry. It is time that we cross the chasm and adopt the technological advancements of the transistor.

What is Microwave Heating?

Before we jump into the magical possibilities of GaN solid-state technology, let us take a step back and understand what microwave heating is. Microwave heating is a Multiphysics phenomenon that involves electromagnetic waves and heat transfer; any material exposed to the electromagnetic field creates vibration and rotation of the polarized molecules inside the material. This friction between molecules increases the temperature of the material, thus heating it. Most materials like food, biological tissues, chemicals, and drugs have high-water content, allowing them to readily absorb microwave energy.

What are the advantages of GaN Solid State vs. Magnetrons?

Magnetron tubes have an approximate lifetime of only a few thousand hours, from 1,500 to 6,000 hours, depending on the tube and application. Due to their short lifetime, they must be replaced frequently, resulting in costly downtime and repairs. GaN solid-state microwave systems, on the other hand, are designed to last more than 50,000 to 100,000 hours. Also, unlike magnetrons that require high voltages (4~15 kV), GaN solid-state microwave systems only require a low voltage of 50V, resulting in safer operations and significantly lowering costs.

Lastly, RFHIC’s GaN solid state technology’s most significant advantage is its capability to control the frequency, phase, power, and signal source precisely and digitally. This next-generation technology will host new profound capabilities such as frequency sweeping, band mapping, and pulse width modulation, resulting in optimized end products.

What are the Drivers and Market Opportunities using GaN Solid State Technology?

The possible microwave applications utilizing GaN solid state are endless – from food processing to growing artificial gemstones. The microwave heating market is expected to reach $1.6 billion by 2027. The main drivers are expected to come from food & beverage, plastics, chemicals, and the paper industry.

Food & Beverage

The food & beverage industry has witnessed tremendous growth in the past few years and is expected to reach $7.5 trillion by 2023. One of the major factors driving this growth is the rising preference for processed foods over unprocessed foods due to consumers’ changing lifestyles. However, consumers demand higher quality and more nutritional processed foods made with real ingredients.

With this increase in demand, major food companies are aggressively adopting newer and more profound technologies to benefit the food & beverage industry. Industrial microwave heating can be used for multiple applications within the food and beverage industry, to name a few – microwave drying, pasteurization, sterilization, tempering, cooking, blanching, and much more.

Previously, magnetrons were the only viable power source for food and beverage applications due to their high power and efficiency. With technological advancements, solid-state devices are starting to provide better or equivalent results in reliability, efficiency, power, and costs.

RFHIC’s Low Cost, Efficient, and Powerful (L.E.A.P) GaN solid-state technology will transform food and beverage processing.

Benefits Include

- A significant increase in processing efficiency due to its instantaneous heat-up time, shortening overall processing time.

- Due to their shorter processing time, foods and beverages require fewer additives (ex., Salt, vitamins), reducing costs while creating more nutritional end products.

- Much more uniform heating & cooking, resulting in higher quality end products.

- Microwave heating can extend the shelf life of foods and beverages, decreasing global food waste significantly.

- Lower carbon footprint as microwave equipment consumes less energy vs. conventional methods

Learn More Check out our GaN Solid State Portfolio for Food & Beverage Applications

Ablation Technology

The global ablation technology market is projected to reach USD 4.73B by 2021, with a growing CAGR of 10.9%. The rising incidence of cancer and an ever-increasing prevalence of cardiovascular diseases are major factors driving the ablation technologies market.

The ablation market is categorized into laser/light, radiofrequency, cryoablation, microwave, and hydrothermal ablation technology.

Among them, the microwave ablation segment is expected to grow at the highest rate due to the many advantages it offers

- Faster heating over a larger volume

- Less susceptibility to heat sinks

- Enhanced multiple applicator support and no requirement for ground pads.

- High Reliability

Microwave ablation generators utilize one of two power sources: a magnetron or solid-state amplifier. However, magnetrons require a high-voltage power supply, which often entails a bulky and heavy transformer. RFHIC’s GaN solid state generators, on the other hand, require a low voltage power supply of 50V, reducing size significantly. Our GaN solid state generators are fabricated using our cutting-edge gallium nitride (GaN) on silicon carbide (SiC) transistors, enabling excellent thermal stability, up to 68% efficiency, and power levels capable of up to multi-kWs.

Learn More Check out our GaN Solid State Portfolio for Microwave Ablation

Microwave Plasma

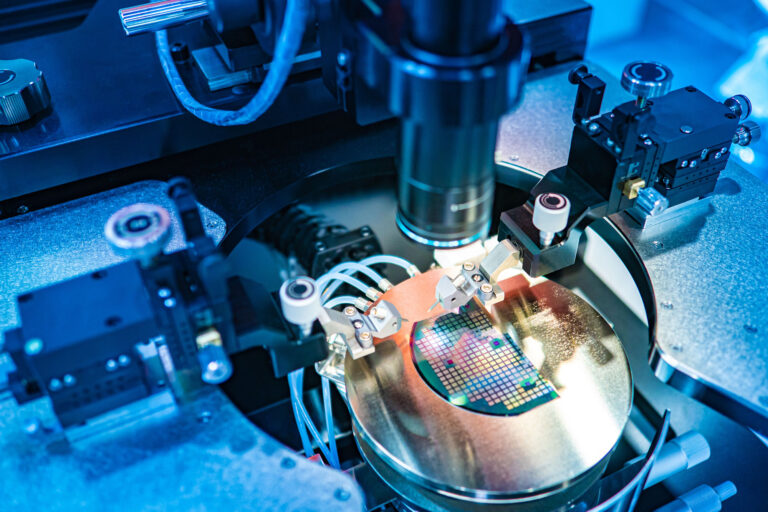

Microwave plasma is one of the application areas of significant economic value in the industry and promises for the future. Plasmas, sources of active ions and free electrons, enable many applications in research projects and commercial sectors. The most widespread application of RF and microwave plasmas is within the semiconductor industry, where plasmas are utilized for:

- Chemical vapor deposition (CVD) of amorphous silicon films used in solar cells

- Deposition of silicon nitride for surface passivation and insulation

- Anisotropic etching in the fabrication of microelectronic chips

- Surface oxidation used in the fabrication of silicon-based microelectronic circuits

Sustain plasmas, and microwave energy has several advantages compared to conventional technology.

- Microwaves have higher ionization efficiency than RF for a given plasma, especially at lower pressures.

- Due to the lack of electrodes, the risk of contamination and damage to sensitive applications is lower.

- Lower ion energies can reduce damage in wafer processing.

- Its higher power capabilities allow for faster growth rates, enabling faster and easier scalability.

Explore more about our High Power Microwave Plasma Sources

Future Outlook and Conclusion

Over the last 75 years, the Magnetron has been the main and only successful source for microwave energy despite its many limitations (frequency stability, short lifetime, and reliability). But now, all that has changed thanks to the advancements of the transistor.

Now, solid state power sources can provide up to multi-kWs of power with efficiencies up to 66% in both mid to high band frequency ranges (900-930 MHz, 2.4-2.5GHz, 5.8GHz).

Gallium nitride (GaN) solid state microwave sources will give us the ability to overcome system design constraints and embark upon a new generation of discovery and innovation, further broadening the scope of microwave power applications.

So goodbye, Magnetron, and hello GaN Solid-State!