There are many use cases for microwaves in semiconductor applications, from annealing to etching to remote plasma deposition. The possibilities are endless. Our customers in the semiconductor industry are looking for reliable microwave sources that adapt to the changes in how semiconductors are manufactured. For the most part, magnetron has been the main source for various semiconductor applications in lower frequencies. However, the age has come for solid-state technology to help engage the ever-evolving semiconductor market.

Thermal Process

The thermal process has various roles within the semiconductor world. It can help wafers put back into correct formation and prepare them to receive new materials. Many frequencies are used for this microwave heating application, most commonly 915MHz and 2.45GHz. Some have shown theoretical advantages of using 5.8GHz due to frequency influence on the dielectric properties of the materials. Also, frequency has an inverse relationship to penetration depth, meaning that the higher the frequency, the more the penetration depth decreases. This could be ideal for selective heating of very thin layers deposited onto a substrate. There are various methods of heating using a microwave. The two main methods are variable frequency microwave and microwave induction heating. These heating methods have tremendous advantages in the semiconductor process due to the control of penetration depth and the ability to heat materials almost five times faster than conventional radiant methods. The variable frequency microwave method sweeps across the bandwidth very fast (in milliseconds) to create uniform heating without getting the concentrated hot spots like you would on your microwave ovens.

The other method is induction heating, which is very similar to the induction cooktop, yet the frequency is much higher. Microwave induction heating, also known as electromagnetic induction heating (EMIH), can be advantageous over conventional RTP chambers that use external radiant heat sources in the sense that the presence of insulating layers will not hinder the heating because the wave transmits through the insulator and directly into the material that needs to be heated.

Plasma Assisted Process

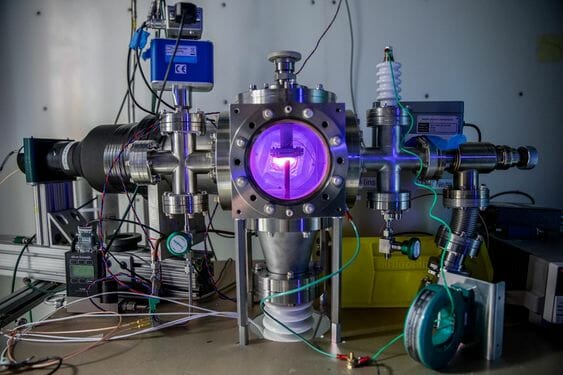

For the most part, the plasma-assisted process is still considered one of the thermal processes. The difference is that it uses plasma and its unique ability to ionize gas for deposition and/or etch away unwanted materials. On this topic, the focus is on microwave plasma; higher frequency plasma has higher plasma density and lower penetration depth. There are many forms of deposition in the semiconductor industry. Most are utilized for thin film deposition on wafers in various formats. Many of these processes are different from each other in how the chemical reaction is initiated.

Microwave Plasma Chemical Vapor Deposition (MPCVD)

Currently, many companies are trying to utilize the solid state’s advantage for microwave plasma-assisted CVD (MPCVD) to produce diamond gemstones. Unlike many semiconductor processes, where the longest processes may not exceed one day, continued operation for 5 to 10 days is necessary for diamond growth. During that time, any equipment failure may jeopardize the batch completely. It is also important for semiconductor equipment to operate at little to no margins every time it is used. This type of operation may be difficult for magnetron sources where frequency may shift depending on the lifespan or even the condition it operates. SSPA can mitigate such issues with precise frequency control to match the recipe required for the specific process.

There are various ways GaN solid-state technology can play in the semiconductor equipment market. It creates a circular supply chain where the materials produced by the equipment are utilized to power the equipment. RFHIC is pursuing to take part in improving and enhancing the semiconductor industry with our GaN solid-state industrial microwave generators.